CO140H24S – Circle Hole Capped Composite Decking – Grey

Capped composite decking, also known as WPC co-extrusion decking. The surface treated with co-extrusion technology is more wear-resistant and durable. Sanded surfaces with double color design. With hollow-core honeycomb design, our WPC hollow decking is Lightweight and solid.

Color Options: Original Wood, Black, Dark Grey, Red pine, Redwood, White, Coffee, Light Grey, Blue Grey, Art color or customized.

Type: Circle hole capped composite decking

Size: 140×24mm

Length: 2.4m, 2.9m, 3.6m, 4m, or customized

Applications: park, landscape, water park, garden, outdoor platform, etc.

Ingredient: 60% wood fiber, 30%HDPE, 10% chemical additives

Certificates: FSC, CE, ISO 90012008, SGS

Profile: Circle hole hollow decking

- DETAILS

- Product Gallery

- FAQ

- INSTALLATION GUIDE

- TECHNICAL SPECS

- Get Price Form

- Product Relacted Parts

Description

Main Material

The composite decking board is made of wood fiber and recyclable plastic. It consists of 60% wood fiber, 30%HDPE, and 10% necessary chemical additives. There are no harmful substances in it that are completely eco-friendly. It owns strong durability, corrosion resistance, waterproof, insect resistance, fireproof, etc. The processing performance is similar to the original wood, and can be cut, drilled, etc., which is convenient to use.

Advantages

Wood effect composite decking looks similar to the original wood. And they share a similar processing performance. Composite decking boards can also be shaved, nailed, drilled, and cut.

Easy installation with low cost, and there are no regular maintenance requirements.

Long-lasting moisture resistance, corrosion resistance, UV resistance, impact resistance, can effectively prevent insects and termites. Not easily worn, deformed, or broken.

Strong fire resistance with a fire-proof rating B. High flame-retardant, self-extinguishing in case of fire, it won’t be an ignition material to ignite other items.

Good weather resistance, suitable from -40℃ to +60℃.

No painting or gluing need.

Good anti-slip properties, barefoot-friendly.

Renewable and durable materials. With correct installation and maintenance, its average usage time is five times longer than traditional wood.

High cost-effectiveness. 1/2 to 1/3 of wood cost & low maintenance requirements.

Strong color fixation and dimension stability against moisture and temperature changes.

[Attached: Supplementary Information-Fireproof Material Grade]

Class A: Non-combustible building materials, materials that hardly burn.

Class B: Flame-retardant building materials: Flame-retardant materials have a good flame retardant effect. It is difficult to catch fire in the air or under the action of high temperature, and it is not easy to spread quickly, and the combustion stops immediately when the fire source is removed.

Class C: Flammable building materials: Flammable materials have a certain flame retardant effect. When exposed to an open flame in the air or under the action of high temperature, it will catch fire immediately, which will easily lead to the spread of fire, such as wooden pillars, wooden roof trusses, wooden beams, wooden stairs, etc.

Product Gallery

The Most Popular Composite Fencing Applications

Unifloor is a professional composite decking manufacturer and supplier in China. We provide Hi-tech and Eco-friendly WPC decking for worldwide customers.

Commercial Composite Decking

Ideal option for commercial space

Balcony Composite Decking

Specially designed for your balcony

Garden Composite Decking

A good place to enjoy outdoor time

FAQ

General Information

Please contact us for the specification list.

Yes, we can, all of our samples are free, but the freight cost is owned to you.

You can choose the samples directly from our stock, or we can do the sample according to your required color design.

Yes, we can. We provide a large number of choices, but in order to meet more needs, we also provide customized services. Please contact us for more details.

Yes, our factory is located in Zhejiang Haining City, it covers 80000 square meters. We have 58 extrusion production lines. Now, we cooperate with wholesalers all over the world. Welcome to visit our office in Shanghai.

Composite wood decking costs more than traditional timber decking because of its higher cost of materials and manufacturing, also the cost of necessary chemical additives for stronger durability and longer usage.

Product Information

Our WPC products are made of 30% HDPE + 60% Wood Fibers + 10% Chemical Additives.

We apply the latest technology, but our price is favorable.

During the manufacturing process, our QC will check the size, color, surface, the quality, then they will get a piece of sample to do a mechanical property test. The quality will also be checked after treatment.

It is about 25-30 years under ideal situations.

It is recyclable which is friendly to the environment. It performs well in waterproof, moisture-proof, moth-proof, and weather-resistance, etc.

Customized Service

Generally, the length and color of products can be customized according to your requirements. If you have other specific requirements, the mold needs to be provided. You can order our free samples before you order for customization.

Yes, the following two conditions are required:

Material Area: 1000 total Square Meters

Lead time: 6 weeks

Purchase

TT 30% deposit and 70% balance before shipment or against the B/L copy.

L/C at sight.

any other payment methods, please kindly remind in advance, it can be negotiated.

Delivery Information

Usually 10-15 days after receiving a 30% deposit for one 20ft container (nearly 850 square meters goods), this time can be reduced to 7 days if the order is regular, so that we could arrange the product works in advance.

Installation

Actually the installation is quite easy, both wall panel and decking, only require a simple tool like an electric drill, clips, and screws. You can finish the installation quickly, generally, 2 people are enough to complete about 50 square meters of wall panel/decking.

Maintenance

Wood plastic composite material performs well in weather resistance and UV resistance, but prolonged exposure will inevitably affect its color. Among wood-plastic composite decking, co-extruded composite decking is the best in terms of fade resistance.

As the difference with the wood, WPC products themselves own color, they don’t need extra painting. Generally, we provide 8 main colors as cedar, charcoal, chocolate, coffee, gray, light gray, redwood, wood. And also, we can make special color per your request.

Our composite products are low-maintenance, they do not need to be sealed, painted, or oiled regularly.

Compared to traditional wooden decking, composite decking requires little maintenance. Regular cleaning can keep longer tidiness and longer use. All you need for cleaning your decking area is a hard brush, soapy water, a bucket of warm water, airy space in warm and dry weather.

INSTALLATION GUIDE

Durable wood plastic composite products have both the texture of wood and the toughness of the plastic. With proper installation and maintenance, it can last about 25-30 years. Installation guide for composite decking.

Required Materials & Tools:

Composite Decking Board

Composite Decking Joists

Hidden Fasteners: composite decking starter clips; composite decking clips; composite decking screws; expansion screw

Edge Boards: composite decking edge trim

Rubber Hammer

Drill

Installation Steps:

Before installation, please harden the ground in advance and make sure it is flat.

Step 1 Fixing Joists

Determine the spacing between the two joists, 30cm is recommended for square hollow decking; 35cm for round hollow decking, and 40cm for solid decking. The spacing can be shortened as requested. Then, drill joists and fix them with expansion screws.

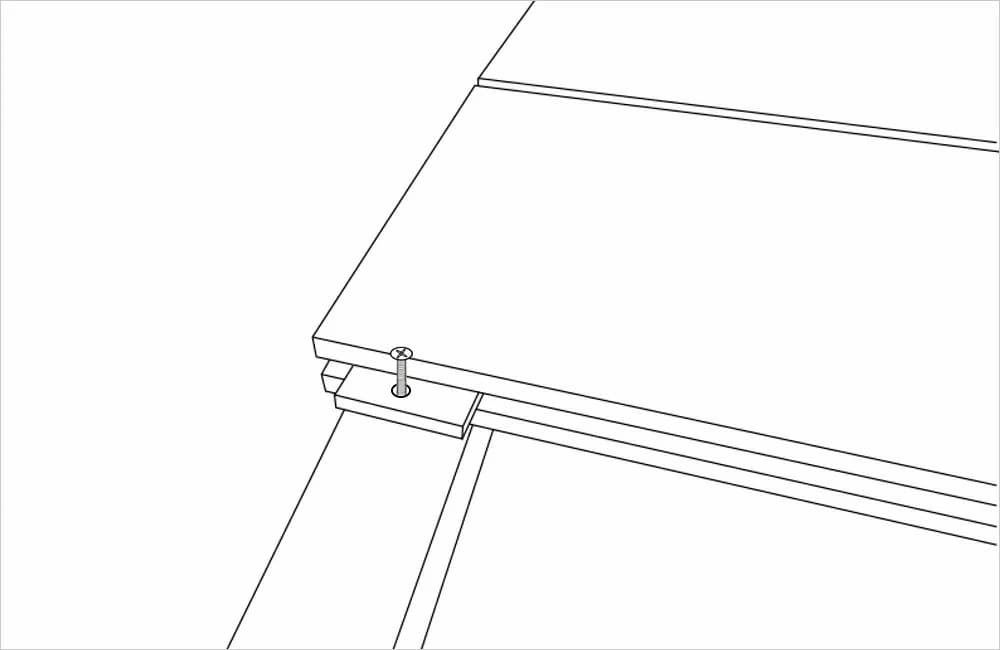

Step 2 Installing WPC Decking

1. When installing composite decking panels, a distance of 3cm should be maintained from the building.

2. Placing the first deck board to start your installation.

3. Connecting the two boards with plastic T clips & screws, the diameter of the hole should be less than 3/4 of the diameter of the screw to enhance the grip of the screw. The plastic T clips & screws are used to fix the spacing between the two boards to prevent sliding. (Knock the boards gently with a rubber hammer during the installation process to achieve equal gaps and a beautiful surface.)

4. Repeat this process until the last board. Then comes to the last step, set the edge boards on decking, and fix them with screws, then the installation is complete.

Other points to note:

- Install decking with safety equipment.

- It is easier to carry with decking edges.

- Consult supplier for recommended tools.

- Do not dump the decking material when unloading.

- Refer to local building regulations before installation.

- Scrap can be discarded with normal construction debris.

TECHNICAL SPECS

Data sheet | |||

PRODUCT SPECIFICATION | |||

Item | Standard | Requirements | Result |

Slip Resistance Dry | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 EN 15534-4:2014 Section 4.4 | Pendulum value≥36 | Longtitudinal direction:Mean 72,Min 70 Horizontal direction:Mean 79,Min 78 |

Slip Resistance Wet | EN 15534-1:2014 Section6.4.2 CEN/TS 15676:2007 EN 15534-4:2014 Section 4.4 | Pendulum value≥36 | Longtitudinal direction:Mean 46,Min 44 Horizontal direction:Mean 55,Min 53 |

Falling mass impact resistance | EN 15534-1:2014 Section7.1.2.1 EN 15534-4:2014 Section 4.5.1 | None of the speciments shall a failure with a crack length≥10mm or a depth of residual indentation≥0.5mm | Max.Crack length(mm):No crack Max.Residual indenation(mm):0.31 |

Flexural properties | EN15534-1:2014 AnnexA EN 15534-4:2014 Section 4.5.2 | -F’max:Mean≥3300N,Min≥3000N -Deflection under a load of 500N Mean≤2.0mm,Max≤2.5mm | Bending Strength:27.4 MPa Modulus of elasiticity:3969 MPa Maximum load: Mean 3786N,Min 3540N Deflection at 500N: Mean:0.86mm,Max:0.99mm |

Creep behaviour | EN 15534-1:2014 Section7.4.1 EN 15534-4:2014 Section 4.5.3 | Known span in use: Mean ∆S≤10mm,Max ∆S≤13mm, Mean ∆Sr≤5mm | Span: 330mm,Mean ∆S 1.65mm,Max ∆S 1.72mm,Mean ∆Sr 1.27mm |

Swelling and water absorption | EN 15534-1:2014 Section8.3.1 EN 15534-4:2014 Section 4.5.5 | Mean Swelling:≤4% in thickness,≤0.8% in width,≤0.4% in length Max swelling:≤5% in thickness, ≤1.2% in width,≤0.6% in length Water absorption:Mean:≤7%,Max:≤9% | Mean Swelling:1.81% in thickness,0.22% in width,0.36% in length Max Swelling:2.36% in thickness,0.23% in width,0.44% in length Water absorption:Mean:4.32%,Max:5.06% |

Boiling Test | EN 15534-1:2014 Section8.3.3 EN 15534-4:2014 Section 4.5.5 | Water absorption in weight: Mean≤7%,Max≤9% | Water absorption in weight: Mean:3.06%,Max:3.34% |

Linear thermal expansion coefficient | EN 15534-1:2014 Section9.2 EN 15534-4:2014 Section 4.5.6 ISO 11359-2:1999 | ≤50×10⁻⁶ K⁻¹ | 34.2 x10⁻⁶ K⁻¹ |

Resistance to indentation | EN 15534-1:2014 Section7.5 EN 15534-4:2014 Section 4.5.7 | Brinell hardness: 79 MPa Rate of elastic recovery:65% | |

Heat reversion | EN 15534-1:2014 Section9.3 EN 15534-4:2014 Section 4.5.7 EN 479:2018 | Test Temperature:100℃ Mean: 0.09% | |

Get Price Form

Get Price And Free Samples Right Now!

UNIFLOOR is the leading Wood-plastic composites manufacturer from China, contact us to get a quote and samples. If our standard size and color options do not perfectly match what you are going for, we can also provide customized services.

Product Relacted Parts

You May Also Need